Moving machinery can be a daunting task, but with proper planning and preparation, you can ensure a smooth transition. Whether you're relocating your business, upgrading your equipment, or simply rearranging your workspace, moving machinery requires careful attention to detail. Discover the essential steps to ensure a smooth machinery move.

1. Assessing your Equipment

Before diving headfirst into the moving process, take the time to thoroughly evaluate your machinery. Create a detailed inventory of all the equipment you need to move, including their specifications, dimensions, and any special handling requirements. This will help you determine the logistics and resources needed for a successful move.

Additionally, consider conducting a thorough inspection of each piece of machinery to identify any potential issues or maintenance needs. This will allow you to address any necessary repairs or adjustments before the move, ensuring that your equipment is in optimal condition.

2. Plan Ahead

Preparing for a machinery move involves more than just packing and transport. Start by establishing a timeline and setting clear objectives for each stage of the move. Consult with your team and relevant stakeholders to ensure a smooth transition without major disruptions to your operations. Remember to account for any downtime and adjust your production schedules accordingly.

In addition to setting timelines, it is crucial to develop a comprehensive moving plan. This plan should outline the specific tasks, responsibilities, and resources required for each stage of the move. By having a detailed plan in place, you can effectively allocate resources, minimize downtime, and ensure a seamless transition.

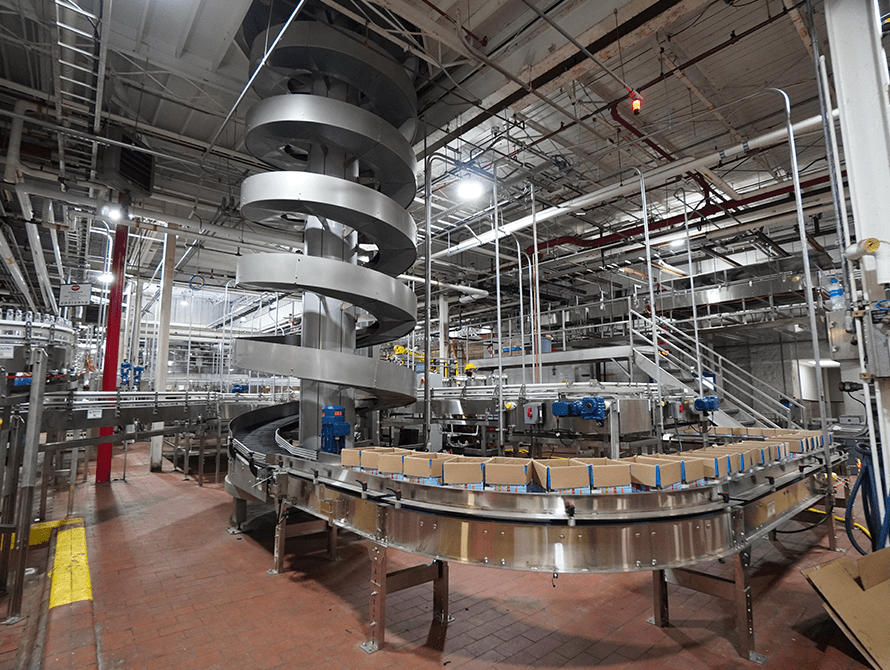

Before attempting to relocate machinery within or out of a building, it is crucial for a customer to conduct a thorough inspection of the surrounding area. Start by checking all doorways, passages, and hallways to ensure they are wide enough to accommodate the machinery without any obstructions. Measure the dimensions of both the machinery and the doorways to guarantee a proper fit. Additionally, identify and remove any obstacles, such as furniture, debris, low-hanging piping, doorways, and overhead obstructions, that may hinder the safe removal and relocation process. This careful assessment and preparation will help streamline the task and prevent potential damage or accidents during the machinery's movement.

3. Engage the Experts

It's tempting to handle the move yourself, but hiring experienced professionals for machinery relocation saves time, stress, and potential equipment damage. Research and select a reliable rigging company with a proven track record in handling similar projects. They will have the necessary expertise and equipment to ensure a successful move.

When selecting this company, consider their experience in handling the specific type of equipment you have. Different machinery may require specialized knowledge and equipment for safe and efficient relocation. Choosing a company with relevant experience can give you peace of mind knowing that your equipment is in capable hands.

4. Prepare Your Machinery

Properly preparing your machinery before the move is crucial for its safety and protection. Start by documenting the current condition of each piece of equipment and taking photographs if necessary. This documentation will be useful for insurance purposes and can serve as a reference point for any post-move inspections.

In addition to documenting the condition, it is essential to follow the manufacturer's guidelines for preparing the machinery for transport. This may involve disconnecting power sources, securing loose parts, and properly packaging or crating the equipment. By following these guidelines, you can minimize the risk of damage during transit.

5. Communicate and Coordinate

Effective communication is the key to any successful machinery move. Keep all relevant parties informed throughout the process, including your staff, machinery moving team, and any external stakeholders. Clearly communicate expectations, timelines, and any specific requirements related to the move. Encourage open dialogue to address any concerns or questions that may arise.

In addition to communication, coordination is essential for a smooth machinery move. Ensure that all parties involved are aware of their roles and responsibilities and establish regular check-ins or progress meetings to track the move's progress. By maintaining open lines of communication and coordinating efforts, you can mitigate potential issues and ensure a seamless transition.

6. Ensure Proper Insurance Coverage

While we always hope for the best, accidents can happen. Protect your investment by ensuring that you have adequate insurance coverage for any potential damages or losses. Review your current insurance policies and consult with your provider to determine if additional coverage is necessary for the move.

When reviewing your insurance coverage, consider factors such as the value of your machinery, the distance of the move, and any potential risks associated with the relocation process. By understanding your insurance coverage and making any necessary adjustments, you can have peace of mind knowing that you are protected in the event of an unforeseen incident.

7. Create a Contingency Plan

Even with the most meticulous planning, unforeseen circumstances can still arise. It's essential to have a contingency plan in place to address any unexpected delays or issues. Consider factors such as weather conditions, road closures, or equipment malfunctions. By having a backup plan, you'll be better equipped to handle any challenges that may come your way.

When creating a contingency plan, anticipate potential risks and develop alternative solutions or courses of action. This may involve identifying alternative routes, having backup equipment on standby, or establishing communication protocols in the event of an emergency. By being proactive and prepared, you can minimize the impact of unforeseen circumstances on your machinery move.

Preparing for a machinery move may seem like a complex undertaking, but with proper planning, organization, and the right support, it can be a manageable process. By following the steps outlined in this blog post, you'll be well on your way to a successful machinery move. Remember to take your time, communicate effectively, and prioritize the safety of your equipment.

Ryan joined the Boulter team in 2016 as a field employee before transitioning to Packaging Shop Supervisor and now Project Manager. With his diverse background in the field and the crating and packaging shop, he is well-equipped to handle the complexities and challenges that come with managing projects of varying scales and requirements.