Production Line Modifications and Rigging Solutions Help Genesee Brewery Increase Output

To keep up with the growing demand for their beer and flavored malt beverage line and to stay ahead in an increasingly crowded market, Genesee Brewery needed to make significant modifications to their production system. Discover why they turned to Boulter to optimize their production lines and install large-scale beverage tanks allowing them to increase output and improve plant efficiency.

Customer Request

As Genesee Brewery continues to grow, they recently embarked on a facility investment project aimed at improving their operations and expanding their capacity. One aspect of this project was upgrading their Seagram's Escapes product line, a popular brand of flavored malt beverages. Another vital component was rebuilding part of their beer packaging lines to increase output and efficiency.

Solution

As a long-standing partner of Genesee Brewery, we were thrilled to be part of this project, leveraging our expertise and experience to deliver the desired results. Our team of experts were involved in various phases of the project, from the installation of new production lines to the modification of existing ones and storing and installing eight 75' tall beverage tanks.

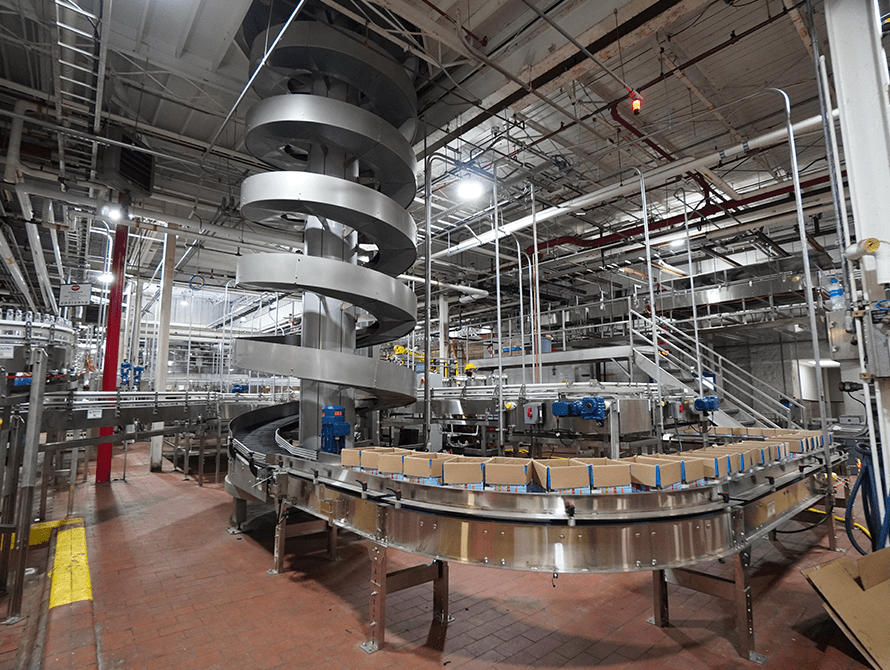

The first phase of the modernization project was dedicated to the Seagram's Escapes product line, which required rebuilding conveyors and installing stainless steel beverage tanks. In the Seagram's Escapes conveyor rebuild project, we installed new conveyors and robots according to drawings and relocated existing conveyors and machinery within the variety pack area. Our expertise and experience allowed us to deliver the desired results for this project with precision and efficiency. For the second part of this project, we offloaded, set, and stored eight 75' tall tanks in our yard until the site was ready, arranged heavy hauling, and transported the tanks to the site. Our five field employees completed the tank installation, including equipment leveling and alignment, and anchoring equipment to the concrete base.

We then returned a few months later with the task of a full line upgrade of another part of the Brewery to improve their production process and increase output. Our team of experts worked closely with the brewery to plan and execute the project with precision and efficiency. This included a complete production line demo, where we dismantled the existing system and prepared the area for the new equipment. We then installed new conveyors and palletizers, carefully transporting and positioning the heavy machinery with the help of our rigging and heavy hauling services. Through meticulous equipment leveling and alignment, we ensured that the new machinery would function seamlessly with the existing systems. The result was a modernized, streamlined production line that has helped Genesee Brewery meet the demands of their growing business.

Project Highlights

- Modified the existing variety pack line to improve plant efficiency

- Stored and transported eight 75' tall stainless steel beverage tanks to be installed in support of the Seagram's Escapes line

- Completed modifications to the existing beer packaging line, including the installation of new palletizers, to support increasing demands

Capabilities Applied

- Production Line Installation

- Steel Fabrication

- Preventative Maintenance

- Warehouse and Storage

- Trucking

Equipment

- Rigging gang box

- Rigging skates

- Slings

- Electric fork truck

- Porta power

- Jacks

- Blocks

- Heel bars

- Rollback retractable curtainside trailer

- Cranes