Quoting a project shouldn't feel like trying to build the plane while it's flying, but for many suppliers, that's exactly what happens when installation isn’t part of the initial conversation. Waiting on rigging quotes, sorting out unclear scopes, and coordinating multiple vendors after the fact can slow down the process and create headaches for both you and your customer.

Every delay opens the door for a customer to rethink their options—or worse, walk away. Today’s buyers expect turnkey solutions. They want fewer phone calls, fewer vendors, and faster decisions. Think about your own life: convenience is king. If you have an insurance broker who calls you every year with updated rates without you even having to ask, it’s a huge time-saver and you're a lot less likely to start shopping around.

It’s no different for your customers. If you don’t have a rigging partner already lined up when you send your quote, you’re not just slowing things down, you’re falling behind suppliers who are making the process easy from day one.

That’s why more suppliers are teaming up with trusted rigging contractors early in the process. When installation support is built into your quote, you move faster, look more complete, and make it easier for customers to say yes.

Why Installation Should Be Part of Your Quote from the Start

Buyers today are looking for one number. They don't want to chase down separate rigging quotes or try to piece together a final budget themselves. If you can hand them a complete package with everything it takes to get operational, you’re immediately making their life easier. And making life easier almost always leads to faster approvals.

It’s important to remember that your customers aren't just managing this one project: they’re also running a plant, hitting production goals, overseeing teams, and solving problems every day. Capital investments like new equipment are meant to make their operations better in the long run, but in the short term, it's one more thing piled onto an already full plate. They’re juggling the install while still handling everything else that can’t afford to slow down. That’s why they’re drawn to suppliers who can simplify the process, not complicate it.

Bundling rigging or installation into your quote isn’t just about convenience, it’s about helping them justify the project internally. When a project comes across management’s desk as one clean package with fewer vendors, fewer quotes, and fewer chances for something to go wrong, it’s a much easier sell. It builds trust that the project will stay on schedule, stay on budget, and actually solve the problem it was meant to fix.

Including rigging or installation services in your quote from day one positions you as a real partner, not just another vendor selling a piece of equipment. And when customers trust that you've thought through the full scope, they're a lot more likely to move forward without hesitation.

What a Rigging Partner Brings to the Table

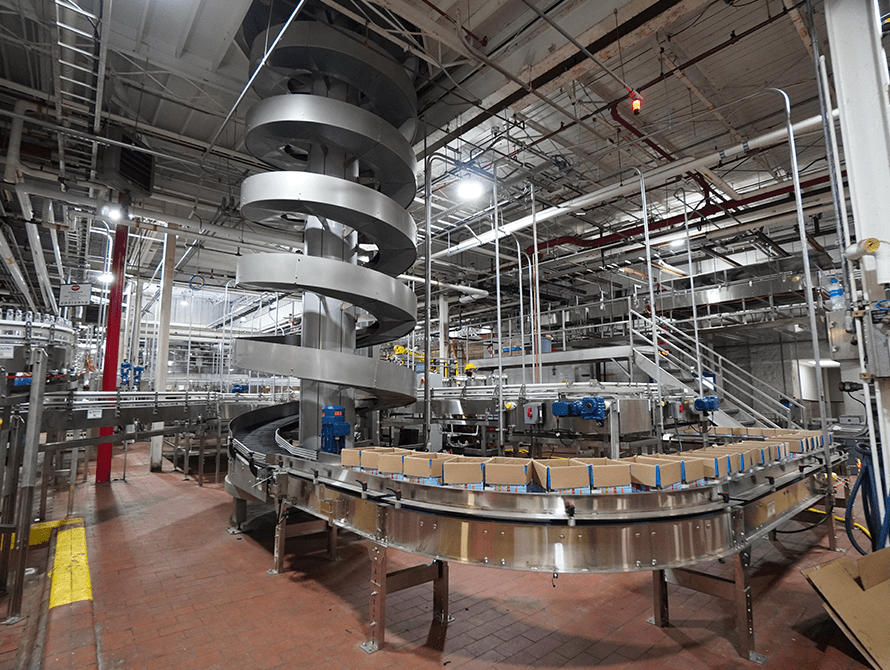

Whether you're supplying a shrink wrapper, palletizer, conveyor system, or a custom tank, getting equipment delivered is only part of the equation. Your customer still has to get it installed and that’s where things can get complicated. Partnering with a rigging contractor ahead of time gives you the ability to offer a smoother, more complete experience from quote to install.

Manufacturing facilities, especially in food and beverage or plastics, often have strict timelines, space limitations, and ongoing production that can't afford extended downtime. Someone who understands these environments can help plan for the real-world variables that impact delivery and installation. Tight quarters, limited access points, off-hours installs, and specialized equipment requirements are all things they’ve dealt with before.

Let’s say your palletizer is ready to ship, and your customer agreed upon a date, but now the site isn’t ready. The space you once allocated for this palletizer is now being utilized by another customer. Here’s another opportunity for your rigging partner to step in. They can receive and store the equipment until your customer’s space is ready, then deliver it in stages to match the production schedule. If a shrink wrapper needs to be rigged in during a third-shift window, they’ll coordinate the equipment and labor without disrupting operations.

Many manufacturers have had bad experiences in the past. Maybe a job ran late, an unskilled crew showed up, or no one communicated clearly. When you bring in a rigging partner you trust, you’re also giving your customer someone they can trust because your name is on it. They chose you for their equipment, which means they already believe in your expertise. That recommendation carries weight, and it opens the door to deeper relationships built on reliability and follow-through. You’re not just selling a machine—you’re solving a problem. And when you can confidently say, “we have the install covered too,” that makes a lasting impression.

Streamlining the Process for Everyone

Projects move faster, and smoother when fewer people are trying to steer the ship. When you partner with a rigging contractor in advance, you’re eliminating gaps in communication and the need for your customer to track down their own resources. That’s a huge value-add for manufacturers who are already stretched thin trying to manage daily operations while overseeing a capital project.

Instead of bouncing between separate quotes for equipment, freight, warehousing, rigging, and install, your customer gets one clear path from purchase to production. That means less time spent coordinating vendors, fewer surprises, and a far lower risk of misalignment along the way. It also means your team isn’t fielding constant questions about install logistics you aren’t equipped to answer.

A strong supplier-rigger partnership also creates a repeatable, reliable process. You can develop consistent scopes, shared timelines, and even templated pricing for common equipment moves. Over time, that makes quoting faster for you and decision-making easier for your customers. In short, you’re helping your customer say yes with less hesitation and helping your team close deals with less friction. That’s a win for everyone.

How to Build a Preferred Rigging Partnership

Building this partnership means finding someone who aligns with how you work, what your customers expect, and the standards you refuse to compromise on. Look for a company that understands the type of work you do and the types of facilities you serve. Installing a conveyor system in a food plant or setting a tank in a tight, enclosed area isn't the same as installing a lathe in a machine shop. You want someone who knows the environment, respects the expectations, and has experience working in active manufacturing settings.

Additionally, this company should prioritize safety and compliance. You wouldn’t put your stamp of approval on someone who looks great on paper but shows up to a food processing facility in sneakers and no hair net. Your reputation is on the line, and who you recommend reflects directly on your business.

Once you’ve found the right fit, consistency is key. Build out shared scopes, pricing structures, and a plan for how to communicate through each stage of a project. The fewer surprises for your customer, the better. When both teams understand timelines, responsibilities, and site needs upfront, it shows in the execution.

It’s also worth developing a repeatable quoting process together. Whether that’s templated pricing for installs, a checklist to define scope or a joint document that clearly outlines responsibilities, it all adds up to less friction and faster approvals. Your internal team will appreciate it just as much as your customers do.

Conclusion

Including installation support in your quoting process gives your company a clear edge. It helps you respond faster, reduce friction, and present a complete solution that your customers can trust. Simplifying the process not only increases your chances of winning but strengthens your reputation as a partner who’s thought through the full picture.

At Boulter, we work with OEMs, equipment suppliers, and integrators to deliver that level of support. Our team of skilled millwrights are ready to take on projects across the Northeast. We’re ready to be your first and final call.

Heading to PackExpo in Vegas? We’ll be there too, and we’d love to connect. Schedule a time to meet with our team and enjoy a drink on us!

Jeremy is a third-generation millwright with over 30 years of field experience, managing some of Boulter's most significant and challenging projects. In 2024, he transitioned to the role of Project Manager, where he now applies his extensive expertise to ensure the successful execution of complex projects from start to finish.