Boulter’s Manufacturing Solutions Help Li-Cycle Expand Operations

Li-Cycle, the largest lithium-ion battery recycler in North America, has developed and patented a unique Spoke and Hub technology to tackle the global battery recycling issue. Discover how Boulter’s expertise in equipment installation and steel fabrication services plays a critical role in getting their Spoke facilities operational.

Customer Request

As society becomes increasingly conscious of the environmental impact of waste, recycling has become a top priority for many industries. One of the major concerns in this area is the recycling of lithium-ion batteries, which are commonly used in electronic devices and electric vehicles. To address this global issue, Li-Cycle, the largest lithium-ion battery recycler in North America, has developed and patented a unique Spoke and Hub technology.

In order to expand the reach of their innovative battery recycling process, Li-Cycle approached our team to install the processing equipment for their Spoke facilities in various locations across the United States.

Solution

We were tasked with providing custom rigging and installation services, as well as steel fabrication and installation services to ensure the Spoke facilities were ready to operate efficiently and effectively.

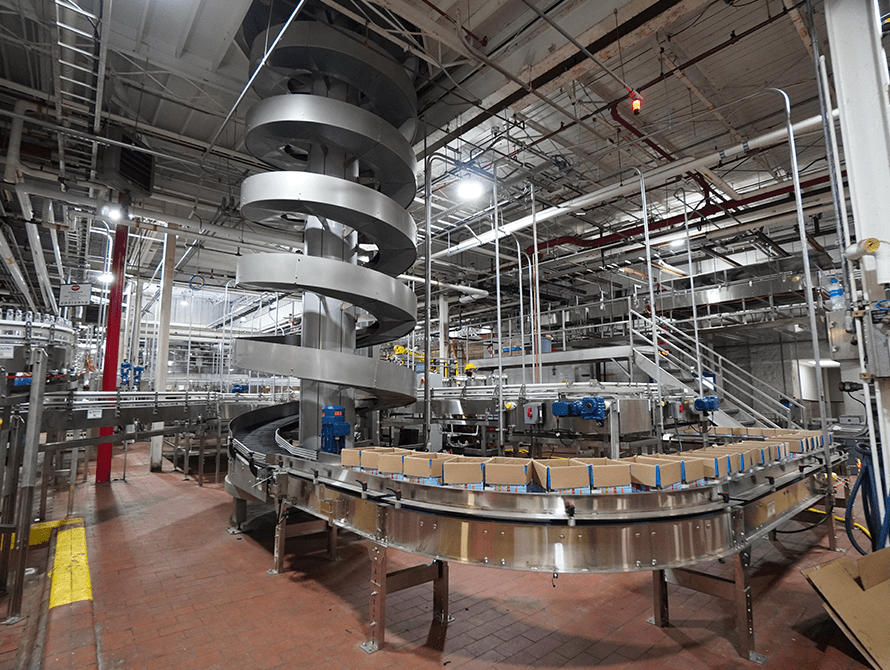

For the Rochester Spoke facility, our team prepared the building for installation by offloading and setting seven skids and conveyor into the second-story opening using cranes and a double hydraulic gantry system. We also provided equipment leveling and alignment to ensure optimal performance. Later, once the site was operational, we provided further support with our steel fabrication and installation services per AISC specifications, including OHSA-compliant stairs, welding completed by certified welders, and necessary modifications to existing handrails.

For the Arizona and Alabama Spoke facilities, we provided custom rigging and installation services to prepare the buildings for installation. Using another double hydraulic gantry system, we offloaded and set skids and conveyor into the building, installed the main feeder conveyor, shredders, and drag link conveyors, and provided equipment leveling and alignment.

Our team was proud to contribute to Li-Cycle's efforts to address the global battery recycling issue by providing top-quality industrial solutions for their unique Spoke and Hub technology.

Project Highlights

- Provided custom rigging and installation services for Li-Cycle's Rochester Spoke facility

- Completed steel fabrication and installation services for stairs and handrails to support the Rochester Spoke facility

- Provided custom rigging and installation services for Li-Cycle's Arizona and Alabama Spoke facilities

Related Case Studies

Capabilities Applied

- Rigging

- Steel Fabrication

- Trucking

Equipment

- Rigging gang box

- Rigging skates

- Slings

- Electric fork truck

- 17-ton shackles

- 3.5-ton fork truck

- Double hydraulic gantry system

- Porta power

- Jacks

- Blocks

- Heel bars

- Cranes